MENUMENU

- Home

- About Us

- Products

- Catalogue

- Product Brochure

- Variable Air Volume

- Volume Control Dampers

- Motorized Control Damper

- Fire Dampers UL 555

- MSFD Class-I

- MSFD Class-II

- TVD Tunnel Ventilation Damper

- Gas Tight Damper

- Sound Attenutors

- Weather Louver

- Sand Trap Louver

- Pressure Relief Dampers

- Access Doors

- Grilles

- Diffusers

- Disc Value

- Filters

- Duct Heaters

- Fire Door

- Certifications

- News/Events

- Projects

- Laboratory

- Careers

- Sales

CONTACT US

MENUMENU

- Home

- About Us

- Products

- Catalogue

- Product Brochure

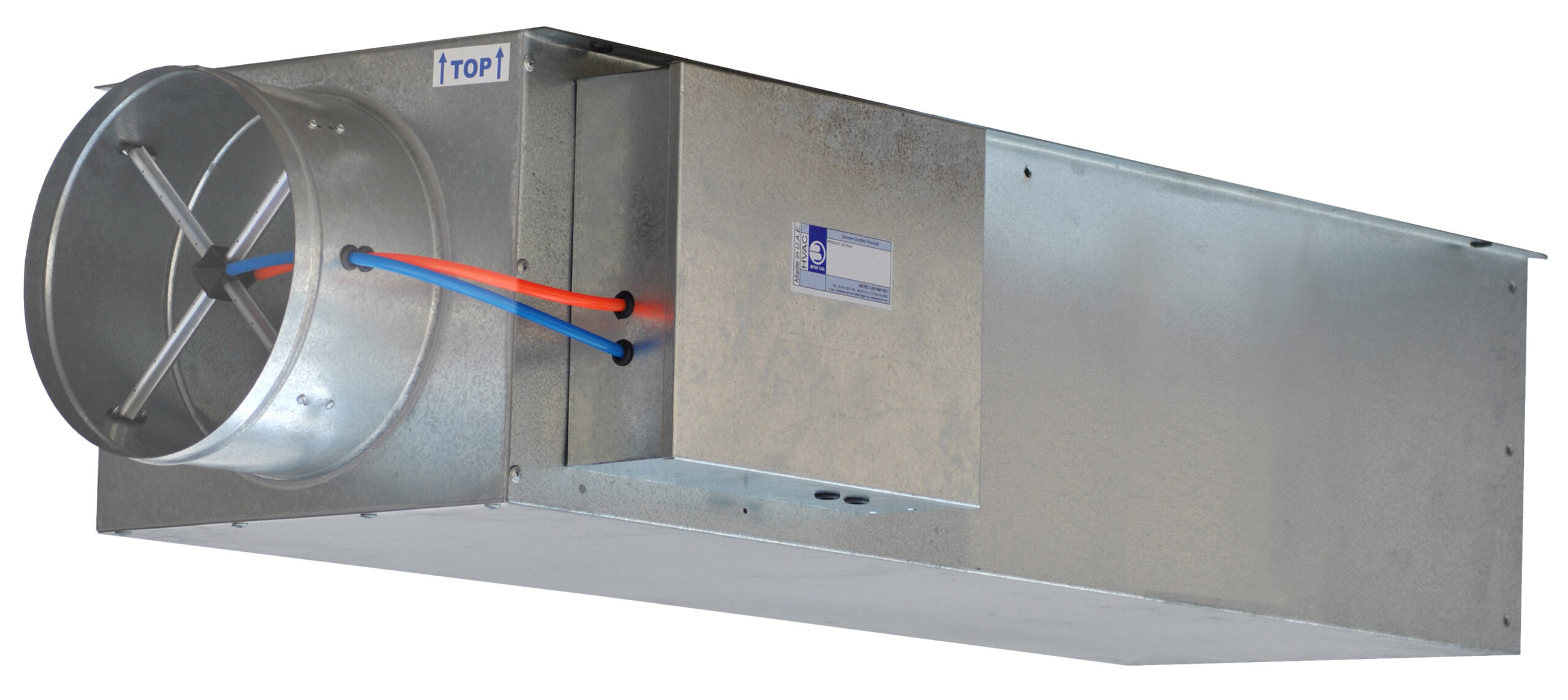

- Variable Air Volume

- Volume Control Dampers

- Motorized Control Damper

- Fire Dampers UL 555

- MSFD Class-I

- MSFD Class-II

- TVD Tunnel Ventilation Damper

- Gas Tight Damper

- Sound Attenutors

- Weather Louver

- Sand Trap Louver

- Pressure Relief Dampers

- Access Doors

- Grilles

- Diffusers

- Disc Value

- Filters

- Duct Heaters

- Fire Door

- Certifications

- News/Events

- Projects

- Laboratory

- Careers

- Sales

ISO 9001 : 2008

CERTIFIED