NUCLEAR FACILITIES

OIL & GAS INDUSTRY

MARINE INDUSTRY

RESIDENTIAL & COMMERCIAL

Projects

Years

Manpower

Manufacturing Locations

R&D investment

Our Story

Meet the Global Standard in HVAC Excellence

Established in 1995 in Sharjah, BETEC CAD has grown into a leading manufacturer and supplier of HVAC (Heating, Ventilation, and Air-Conditioning) solutions across the UAE and beyond. We have continuously expanded our capabilities, offering a diverse range of products, services, and cutting-edge technologies.

With a strong foundation in engineering, we cater to various sectors, including Construction, Commercial, Industrial, Oil & Gas, and Power Plants. Our commitment to quality and innovation ensures that we meet and exceed international standards, delivering excellence in every project.

BETEC CAD where engineering expertise meets global standards.

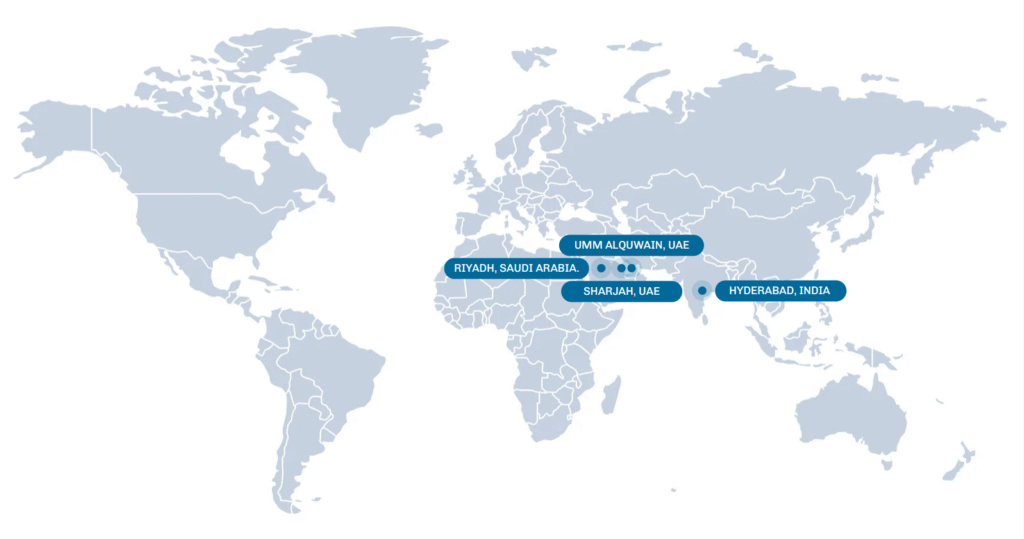

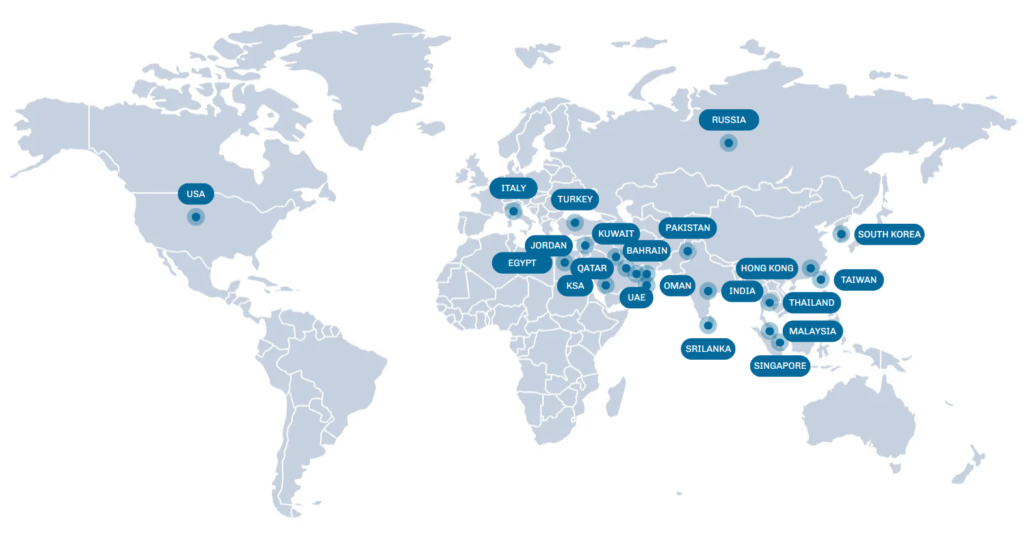

Our Locations

Our global network of offices and warehouses ensures fast delivery and reliable support. Explore the map to find a location near you.

India

Hong Kong

Taiwan

South Korea

Thailand

uae

Qatar

kuwait

KSA

Srilanka

Pakistan

Italy

Jordan

USA

russia

malaysia

Singapore

Egypt

Turkey

Bahrain

oman

Tried to Geocode:

Error Type:

Please be sure to follow the tutorial on how to setup the Google APIs required for the Advanced Google Map Widget.

Google Map API Key TutorialTried to Geocode:

Error Type:

Please be sure to follow the tutorial on how to setup the Google APIs required for the Advanced Google Map Widget.

Google Map API Key Tutorial

India

Hong Kong

Taiwan

South Korea

Thailand

uae

Qatar

kuwait

KSA

Srilanka

Pakistan

Italy

Jordan

USA

russia

malaysia

Singapore

Egypt

Turkey

Bahrain

oman

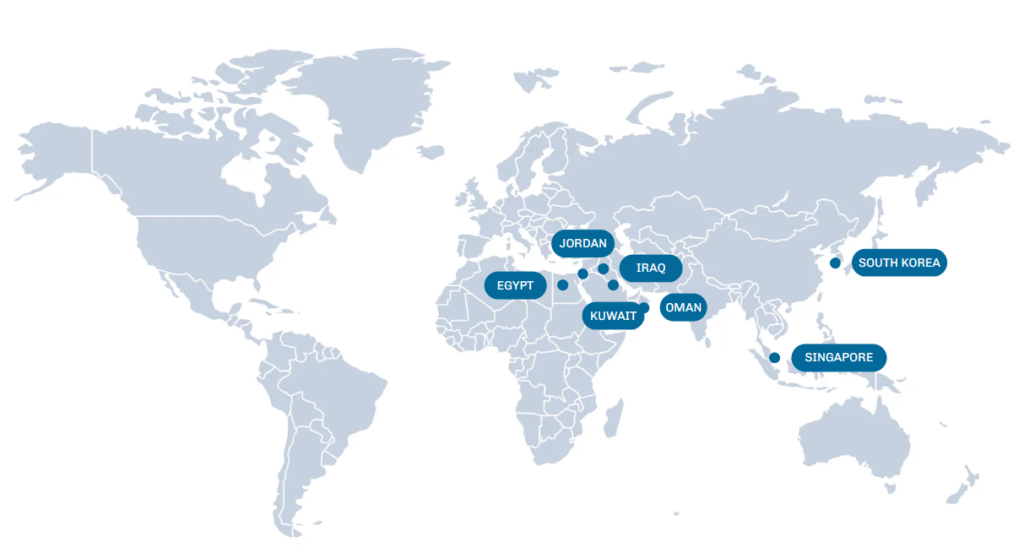

oman

Jordan

Iraq

Singapore

South Korea

Egypt

Kuwait

Tunnel Ventilation Damper

Galvanized construction, stainless steel aerofoil blade, Class 1 leakage at 350° F, 20 in. wg pressure, 4000 fpm velocity, 4 hours fire rating, 250° C for 2 hours.

Marine damper

Stainless steel construction, stainless steel aerofoil blade, 1 hour fire rating per IMO FTP code.

Gas Tight Damper

Galvanized construction, stainless steel aerofoil blade, 1 Oin. wg pressure, 3900 fpm velocity, temperature range of -200 C to 2500 C.

Industries we serve

CATALOGUE

Browse our product catalogue to explore our complete range of dampers and solutions. Download the PDF for detailed specifications and technical information.

Tunnel Ventilation Damper

Galvanized construction, stainless steel aerofoil blade, Class 1 leakage at 350° F, 20 in. wg pressure, 4000 fpm velocity, 4 hours fire rating, 250° C for 2 hours.

Marine damper

Stainless steel construction, stainless steel aerofoil blade, 1 hour fire rating per IMO FTP code.

Gas Tight Damper

Galvanized construction, stainless steel

aerofoil blade, 1 Oin. wg pressure, 3900

fpm velocity, temperature range of -200

C to 2500 C.

Driving Innovation with Creativity and Passion

At the heart of our success lies a relentless pursuit of excellence. Our determination to become a

global leader in HVAC solutions fuel our passion for delivering customized, cutting-edge engineering

solutions tailored to diverse applications. From airports and metros to oil and gas plants, military

and defence facilities, power plants and mixed use commercial buildings, we cater to industries

where precision and innovation matter most.

Through our technical expertise, visionary thinking, and dedication to quality, we continue to push

boundaries. We don’t just meet expectations—we exceed them, shaping the future of engineering

solutions worldwide.

Awards &

Recognization

Product performance award

We also received the prestigious AHRI Product Performance Award, reinforcing our commitment to quality.

Manufacturer of the Year

We were proud to be named Manufacturer of the Year in Fire and Life Safety Products at the Saudi Awards 2024.

Climate Control Award

At the 14th Annual Climate Control Awards 2024, we received an Honorable Mention as Manufacturer and Supplier of the Year.

Business Performance Award

Our consistent excellence earned us the Business Performance Award from Siemens.

Manufacturer of the Year

We were proud to be named Manufacturer of the Year in Fire and Life Safety Products at the Saudi Awards 2024.

Our Partners

Government

Developers

Consultants and Contractors