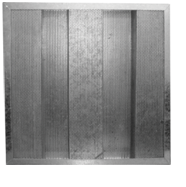

Model :FD-GB/SB/GSB/SGB-22-A/B/AS/BS/R UL 555

Damper meets the required standards of SMACNA,

NFPA, IBC, BOCA, ICBO, UL.

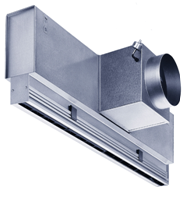

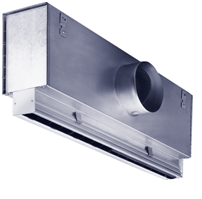

Standard Construction

Frame: 20 gauge (0.9 mm) thick galvanized steel / stainless steel

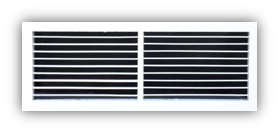

Blades: Curtain type blade made of 22 gauge (0.8 mm) thick galvanized steel / stainless steel.

Fusible Link: 165°F.

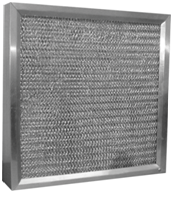

Blade Ramp: 16 gauge (1.5 mm) thick galvanized steel / stainless steel angle.

Spring: 0.3 mm thick by 19 mm wide, stainless steel constant force spring.

Mounting: Vertical

Optional Fittings

Sleeve: Minimum 0.7 mm, single section is field or factory installed.

Multiple section is factory installed.

Sleeve thickness as per NFPA table 3-4.6.3.

Retaining Angles: 1½” x 1½” x 16 gauge (40 x 40 x 1.5) mm.

Limit Switches: For BMS open / close indication.

Transitions (R): Neck adapter for round duct connections