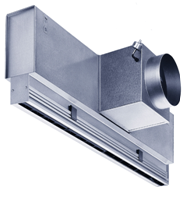

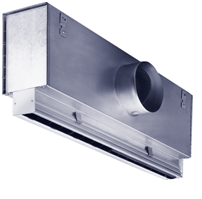

Constant Air Volume with Temperature Variable:

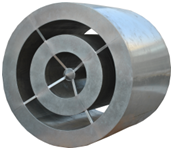

BETEC CAD CAV (Constant Air Volume) unit 50 series Model CAV B 50F is a pressure independent type CAV/VAV with Fan Assisted. These VAV Terminal Boxes were developed to overcome energy limitations, which determined that re-heat could not be applied to air that had already been cooled.

The Operation Of Fan Assisted CAV/VAV Unit:

Primary air is supplied to the VAV terminal boxes in much the same way as with a standard VAV system, but with two exceptions.

The Primary air from the air handling unit need only be supplied with sufficient pressure to reach the VAV terminal box. The pressure resistance after the VAV terminal unit and into the room is maintained by the Fan in the VAV terminal box.

A normal VAV system requires the Air Handling Unit fan pressure to overcome the resistance of the complete system, including duct design after the VAV box and the room diffusers.

With Fan assisted VAV system, the primary air from the air handling unit can be supplied at lower temperature than with the normal VAV systems, as the warm air from the ceiling void can be introduced to mix with the primary air, to give conventional supply of air conditioning from the room diffusers. As the amount of primary air reduces in accordance with the room requirements, the proportion of air induced from the ceiling void increases, so that the diffusers handle a constant volume of air. Re-heat batteries are sometimes fitted to the induction port on the VAV box, so that ceiling void air can be re-heated and mixed with the cool air or fresh air as part of dehumidification.

Data

Constant Air Volume with Temperature Variable:

BETEC CAD CAV (Constant Air Volume) unit 50 series Model CAV B 50F is a pressure independent type CAV/VAV with Fan Assisted. These VAV Terminal Boxes were developed to overcome energy limitations, which determined that re-heat could not be applied to air that had already been cooled.

The Operation Of Fan Assisted CAV/VAV Unit:

Primary air is supplied to the VAV terminal boxes in much the same way as with a standard VAV system, but with two exceptions.

The Primary air from the air handling unit need only be supplied with sufficient pressure to reach the VAV terminal box. The pressure resistance after the VAV terminal unit and into the room is maintained by the Fan in the VAV terminal box.

A normal VAV system requires the Air Handling Unit fan pressure to overcome the resistance of the complete system, including duct design after the VAV box and the room diffusers.

With Fan assisted VAV system, the primary air from the air handling unit can be supplied at lower temperature than with the normal VAV systems, as the warm air from the ceiling void can be introduced to mix with the primary air, to give conventional supply of air conditioning from the room diffusers. As the amount of primary air reduces in accordance with the room requirements, the proportion of air induced from the ceiling void increases, so that the diffusers handle a constant volume of air. Re-heat batteries are sometimes fitted to the induction port on the VAV box, so that ceiling void air can be re-heated and mixed with the cool air or fresh air as part of dehumidification.