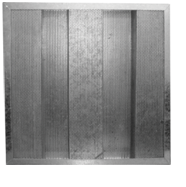

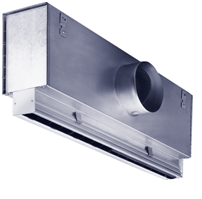

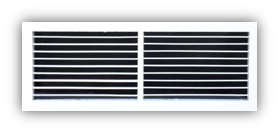

COUNTER BLANACE DAMPERS (CBD-GA-20)

CBD

BETEC CAD. manufactures Pressure Relief Dampers or Non-return dampers or gravity-operated dampers, counter balancing dampers, Self-balancing or Back draft dampers. These dampers are of air / pressure, counter weight operated for opening or closing for intake or discharge or pressure relief vents in central HVAC applications. As the room pressure increases, the blades of the pressure relief damper lifts automatically up there by relieving the excess pressure in the room and as the pressure drops back to normal the blades get closed by gravity or counter weight.

Data

COUNTER BLANACE DAMPERS (CBD-GA-20)

CBD

BETEC CAD. manufactures Pressure Relief Dampers or Non-return dampers or gravity-operated dampers, counter balancing dampers, Self-balancing or Back draft dampers. These dampers are of air / pressure, counter weight operated for opening or closing for intake or discharge or pressure relief vents in central HVAC applications. As the room pressure increases, the blades of the pressure relief damper lifts automatically up there by relieving the excess pressure in the room and as the pressure drops back to normal the blades get closed by gravity or counter weight.