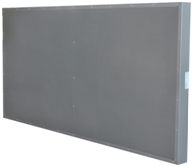

Acoustic Panels – AP – B-40

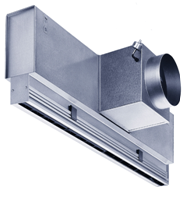

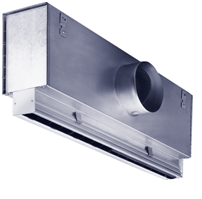

BETEC CAD’s API-B40 models are Acoustic Panels for industrial applications. The aim of developing the Acoustic Panels is to combine acoustic performance with structural durability.

They are manufactured lightweight with firm surfaces, which are extremely strong and resistant to damage.

- All Acoustic Panels are supplied fully assembled, quick and easy to fit producing a clean and neat interior décor presentation.

- BETEC CAD. Acoustic Panels are superbly adaptable for straight walls and even ceilings, and it edges can be shaped to fit almost any design.

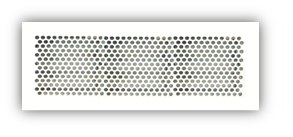

- BETEC CAD. Acoustic Panel is a rigid composite comprising high density sound liner and rock wool mineral fiber surfaces formed in to sandwiched panel and molded in to a galvanized perforated sheet casing.

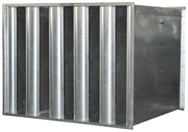

- The acoustic infill material is of fiberglass with 32kg / M³density of thickness 25mm and rock wool with density 48kg / M³,of thickness 50mm formed in a sandwiched panel in compressed form.

Data

Acoustic Panels – AP – B-40

BETEC CAD’s API-B40 models are Acoustic Panels for industrial applications. The aim of developing the Acoustic Panels is to combine acoustic performance with structural durability.

They are manufactured lightweight with firm surfaces, which are extremely strong and resistant to damage.

- All Acoustic Panels are supplied fully assembled, quick and easy to fit producing a clean and neat interior décor presentation.

- BETEC CAD. Acoustic Panels are superbly adaptable for straight walls and even ceilings, and it edges can be shaped to fit almost any design.

- BETEC CAD. Acoustic Panel is a rigid composite comprising high density sound liner and rock wool mineral fiber surfaces formed in to sandwiched panel and molded in to a galvanized perforated sheet casing.

- The acoustic infill material is of fiberglass with 32kg / M³density of thickness 25mm and rock wool with density 48kg / M³,of thickness 50mm formed in a sandwiched panel in compressed form.